Description

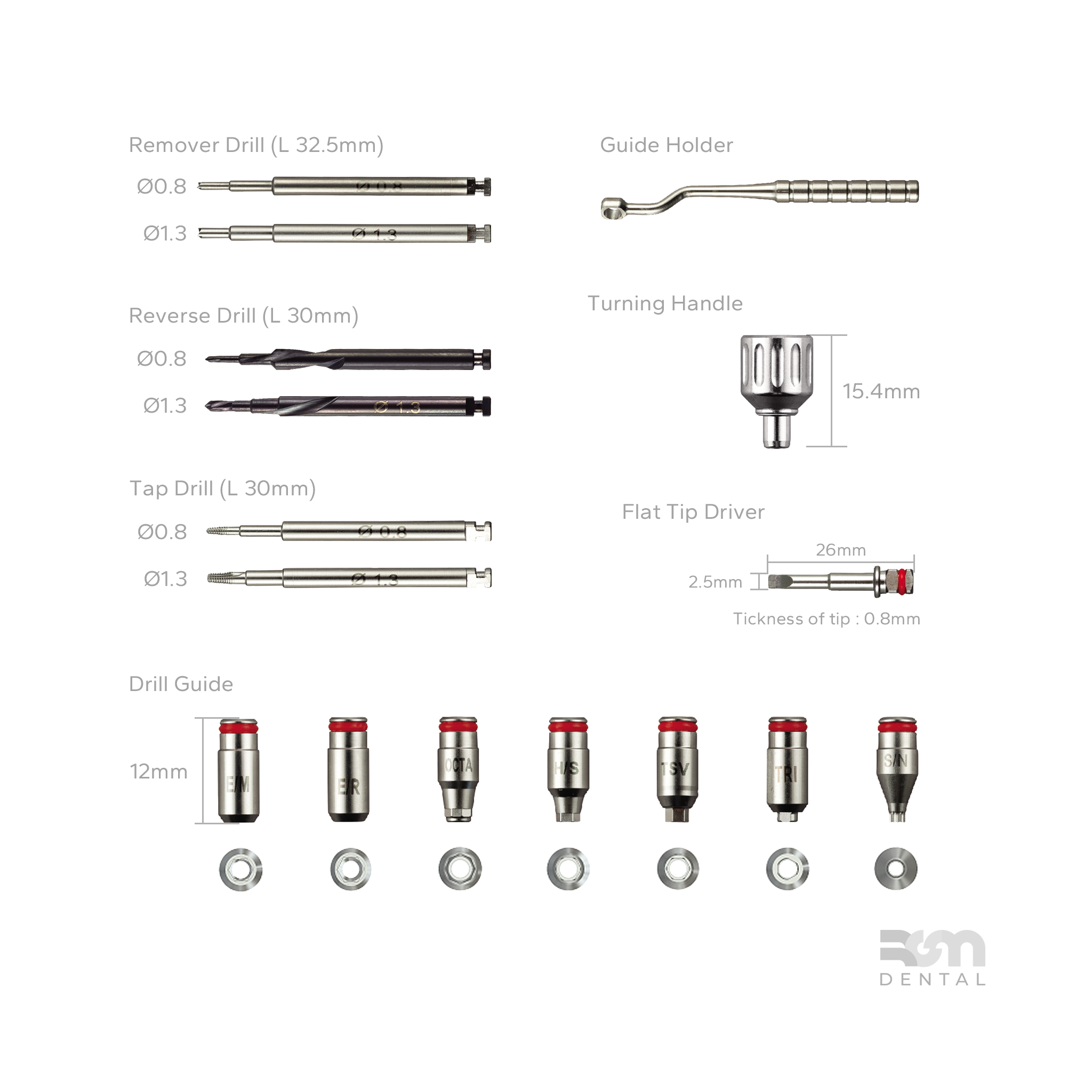

Universal Screw Removal Kit - SURGIDENT®

A variety of screw removal instruments are included which allow clinicians to remove both fractured and stripped prosthetic screws. This kit provides everything.

Screw Removal Components

- Prosthetic guide holder

- Long ratchet wrench

- Adapter (contra Angle to 4mm square)

- Reverse drills

- Reverse taps

- Flat tip driver

- Prosthetic guides (listed below)

External Mini (M)

- Hi-Tec Summit

- Nobel Biocare Branemark System NP

Octa Internal (O)

- Hi-Tec Tite-Fit & Tapered Tite-Fite

- Straumann ITI Tissue Level

- Implant Direct SwishPlant

TSV 3.7I4.1

- Hi-Tec Logict, Spark, Self-Thread

- BioHorizons Tapered Internal 3.7 and 4.70

- Implant Direct Legacy (3.7 and 4.7 internal hex)

- MIS 3.3. 3.75. and 4.20

- Zimmer TSV 3.7. 4.1 and 4.70

External Regular (W)

- Nobel Biocare Branemark System RPO

Hex Submerged (H)

- Hi-Tec Logic, Implex, ExpertNL

- Nobel Biocare NobelActive

Trilobe 3.5 NP

- Hi-Tec Vision@ 3,5

- Nobel Biocare Tri Lobe@ 3.5

Instructions for Stripped Screw Removal

Stripped screws are generally more difficult to remove than fractured screws because fractured screws are not under compression. The most effective method of removing a stripped screw is to create a flathead channel with a round bur, and then use a flat head driver to reverse the screw out of position.

Step 1

Using a 1/2 round bur in a high-speed handpiece, create a channel on the head of the screw across the diameter of the head, creating a flat head.

Step 2

After the channel is created, use the FTD-01 and ratchet wrench to back the screw out.

Instructions for Fractured Screw Removal

Step 1

Press the remover drill (D-REM) in the reverse direction (under 80rpm) on the top of the fractured screw to reverse the screw fragment out of the screw channel.

Step 2

If the remover drill is unsuccessful: Use the provided guide information to select the correct prosthetic guide -based on the implant platform.

Step 3

Attach the selected guide to the guide handle and engage the connection within the implant.

Step 4

With your handpiece in reverse (1,200-1,300 rpm); create a divot in the top of the screw with the D-REM.

Universal Screw Removal Kit - SURGIDENT®

A variety of screw removal instruments are included which allow clinicians to remove both fractured and stripped prosthetic screws. This kit provides everything.

Screw Removal Components

- Prosthetic guide holder

- Long ratchet wrench

- Adapter (contra Angle to 4mm square)

- Reverse drills

- Reverse taps

- Flat tip driver

- Prosthetic guides (listed below)

External Mini (M)

- Hi-Tec Summit

- Nobel Biocare Branemark System NP

Octa Internal (O)

- Hi-Tec Tite-Fit & Tapered Tite-Fite

- Straumann ITI Tissue Level

- Implant Direct SwishPlant

TSV 3.7I4.1

- Hi-Tec Logict, Spark, Self-Thread

- BioHorizons Tapered Internal 3.7 and 4.70

- Implant Direct Legacy (3.7 and 4.7 internal hex)

- MIS 3.3. 3.75. and 4.20

- Zimmer TSV 3.7. 4.1 and 4.70

External Regular (W)

- Nobel Biocare Branemark System RPO

Hex Submerged (H)

- Hi-Tec Logic, Implex, ExpertNL

- Nobel Biocare NobelActive

Trilobe 3.5 NP

- Hi-Tec Vision@ 3,5

- Nobel Biocare Tri Lobe@ 3.5

Instructions for Stripped Screw Removal

Stripped screws are generally more difficult to remove than fractured screws because fractured screws are not under compression. The most effective method of removing a stripped screw is to create a flathead channel with a round bur, and then use a flat head driver to reverse the screw out of position.

Step 1

Using a 1/2 round bur in a high-speed handpiece, create a channel on the head of the screw across the diameter of the head, creating a flat head.

Step 2

After the channel is created, use the FTD-01 and ratchet wrench to back the screw out.

Instructions for Fractured Screw Removal

Step 1

Press the remover drill (D-REM) in the reverse direction (under 80rpm) on the top of the fractured screw to reverse the screw fragment out of the screw channel.

Step 2

If the remover drill is unsuccessful: Use the provided guide information to select the correct prosthetic guide -based on the implant platform.

Step 3

Attach the selected guide to the guide handle and engage the connection within the implant.

Step 4

With your handpiece in reverse (1,200-1,300 rpm); create a divot in the top of the screw with the D-REM.

Universal Screw Removal Kit

- Regular price

- $1,430.00

- Sale price

- $1,430.00

- Regular price

-

Couldn't load pickup availability